Divers Broyeurs à couteaux

AUTRES GROUPES DE PRODUITS

Configurez votre broyeur à couteaux universel PULVERISETTE 19 à une vitesse de rotation variable 300 - 3000 tr/min adaptée à votre application.

Parmi les nombreux accessoires, choisissez au moins une trémie d'alimentation, un jeu d'outils de coupe, une cassette à tamis et un récipient collecteur.

Trémie d'alimentation

Trémie d’alimentation pour échantillons longs et en vrac en plastique ou acier inoxydable 316L, ou

trémie étanche en acier inoxydable ou en acier inoxydable 316L avec sas et coulisseau en plastique

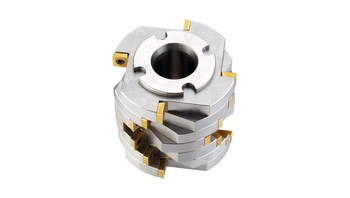

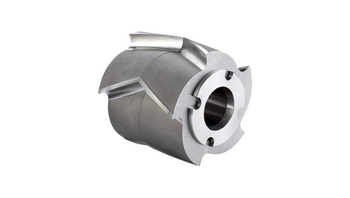

Jeu d'outils de coupe

Rotor avec lames en V et contre-couteaux en acier inoxydable trempé, en métal dur carbure de tungstène et en acier à outil sans chrome ou

rotor avec couteaux droits entaillés et contre-couteaux en acier inoxydable trempé et en acier inoxydable 316L ou

rotor avec couteaux droits et contre-couteaux en acier inoxydable trempé, en acier inoxydable 316L et en acier à outil sans chrome ou

rotors à fraise circulaire avec plaquettes de coupe interchangeables et contre-couteaux en métal dur carbure de tungstène

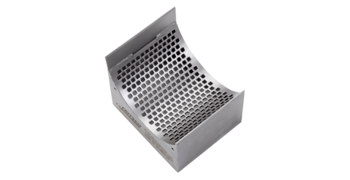

Cassette à tamis

Cassettes à tamis à perforation trapézoïdale ou carrée en acier inoxydable 316L ou en acier sans chrome DC01

Récipient collecteur

Récipient collecteur de 3 litres ou récipient collecteur de grande quantités de 10 litres

Accessoires disponibles en option

Support : support universel, support en acier inoxydable 316L, support à roulettes ou support de table

Aspiration de l'échantillon via des cyclones : Cyclones haute performance ou cyclone pour petites quantités

Certification : Documentation IQ/OQ destinée à aider à la qualification des appareils

Module PLC : Un module PLC permettant de contrôler le broyeur via un système de contrôle PLC et la connexion physique basée sur un bus RS485 sont disponibles sur demande.

TRÉMIES d'alimentation

Vous pouvez équiper la PULVERISETTE 19 d'une trémie d'alimentation en plastique ou en acier inoxydable 316L pour matériaux longs et en vrac pouvant être introduits dans toute leur longueur, ou bien d'une trémie étanche en acier inoxydable ou acier inoxydable 316L avec sas et coulisseau en plastique destinée à tous les autres matériaux.

Trémies d'alimentation

With the FRITSCH standard funnel free-flowing bulk solids as well as straw, films or similar materials can be inserted at full length. Both ends of the plunger of the funnel for long and bulk solids can be utilised: the small end for adding of long goods and the wide end for bulk solids.

| 1. Stopper-Body | |

| General specifications | |

| Material | Aluminium AlZnMgCu1,5 |

| ISO/EN/DIN Code | 3.4365 |

| Chemical composition | |

| Element | Share % | Iron – Fe | 0.50 |

| Silicon – Si | 0.40 |

| Copper – Cu | 1.2 - 2.0 |

| Manganese – Mn | 0.30 |

| Magnesium – Mg | 2.1 - 2.9 |

| Chromium– Cr | 0.18 - 0.28 |

| Zinc - Zn | 5.1 - 6.1 |

| Titan – Ti | 0.20 |

| Physical and mechanical properties | |

| Density | 2.7 g/cm³ |

| Hardness | 2.75 Mohs |

| 2. Fillingtube | |

| General specifications | |

| Material | Stainless steel – 1.4301 |

| ISO/EN/DIN code | X5CrNi1810 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 66.805 |

| Carbon – C | 0.070 |

| Silicon – Si | 1.000 |

| Manganese – Mn | 2.000 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.030 |

| Chromium – Cr | 19.5 |

| Nickel – Ni | 10.5 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 7.8 g/cm³ |

| Hardness | HRB 96 |

Explanations on hardness data

The protected funnel with sample pusher enables due to the sample pusher a good handling and an outstanding material feeding.

| General specifications | |

| Material | Stainless steel – 1.4301 |

| ISO/EN/DIN code | X5CrNi1810 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 66.805 |

| Carbon – C | 0.070 |

| Silicon – Si | 1.000 |

| Manganese – Mn | 2.000 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.030 |

| Chromium – Cr | 19.5 |

| Nickel – Ni | 10.5 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 7.8 g/cm³ |

| Hardness | HRB 96 |

Explanations on hardness data

The protected funnel made in a corrosion-resistant stainless steel version 316L with sample pusher is ideal for applications in the food and pharmaceutical industry. This funnel enables due to the sample pusher a good handling and an outstanding material feeding.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Funnel for long- and bulk solids made in a corrosion-resistant stainless steel version 316L for applications in the food and pharmaceutical industry.

With this FRITSCH funnel free-flowing bulk solids as well as straw, films or similar materials can be inserted at full length. Both ends of the plunger of the funnel for long and bulk solids can be utilised: the small end for adding of long goods and the wide end for bulk solids.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

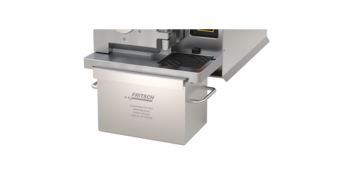

Récipients collecteurs en acier inoxydable 316L

Un récipient collecteur de 3 litres est disponible. Nous recommandons d'utiliser un récipient collecteur de 10 litres pour le broyage de grande quantités. Des récipients collecteurs de différente taille sont disponibles sur demande.

RÉCIPIENTs COLLECTEURs

This collecting vessel has a volume of 3 litres. Collecting vessels (stainless steel are available in various sizes).

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

This collecting vessel is recommended for the comminution of larger sample amounts and has a volume of 10 litres.

Collecting vessels (stainless steel are available in various sizes).

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

JEUX D'OUTILS DE COUPE EN ACIER INOXYDABLE DIFFÉRANT ET CARBURE DE TUNGSTÈNE

-

Caractéristiques des jeux d'outils de coupe et applications recommandées

Matériau et type de rotor Composant principal du matériau Résistance à l'abrasion Densité en/cm³ Convient au broyage de Acier inoxydable trempé Fe - Cr relativement bonne 7,7 Rotor standard avec lames en V et contre-couteaux

référence 45.5100.00

Rotor avec couteaux droits entaillés et contre-couteaux

référence 45.5192.00

Rotor avec couteaux droits et contre-couteaux

référence 45.5185.00échantillons mi-durs, cassants, matériaux et films viscoplastiques

échantillons moyennement durs, cassants, fibreux et élastiques ainsi que les échantillons présentant une humidité résiduelle, par exemple les denrées alimentaires, les aliments pour animaux ou les plantes provenant d'échantillons sensibles à la température, par exemple les plastiques

échantillons mi-durs, cassants, matériaux facilement sectionnables de type foin, paille, matériaux fibreux et biologiquesAcier inoxydable 316L

Les rotors en acier inoxydable 316L sont :

• parfaits pour le secteur analytique

• particulièrement résistants aux alcalis et aux acides

• conformes aux directives de l'industrie alimentaire et pharmaceutique

• résistance accrue à la corrosionFe - Cr relativement bonne 8,0 Rotor avec couteaux droits entaillés et contre-couteaux

référence 45.5198.00

Rotor avec couteaux droits et contre-couteaux

référence 45.5199.00convient au broyage de - voir ci-dessus

convient au broyage de - voir ci-dessusMétal dur carbure de tungstène WC très bonne 12,4 Rotor avec lames en V et contre-couteaux

référence 45.5370.00

Rotor à fraise circulaire avec plaquettes de coupe interchangeables et contre-couteaux

référence 45.5200.00

Rotor à fraise circulaire pour gros échantillons avec plaquettes de coupe interchangeables et contre-couteaux

référence 45.5201.00échantillons durs et abrasifs, matériaux durs-résistants

échantillons durs, abrasifs, broyage des déchets de platines qui contiennent des restes de fibres de verre et de câbles en cuivre

plus grandes quantités d'échantillons durs, abrasifs, broyage des déchets de platines qui contiennent des restes de fibres de verre et de câbles en cuivreCaractéristiques des jeux d'outils de coupe de broyage sans chrome et applications recommandées - voir ci-dessous

Le broyeur PULVERISETTE 19 peut être équipé soit d'un rotor avec lames en V ou avec couteaux droits, rotor avec couteaux droits entaillés et contre-couteaux, soit d'un rotor à fraise circulaire. Le choix du matériau des rotors de coupe et des contre-couteaux permet d'influencer le comportement à l'abrasion au cas par cas. Tous les détails concernant les rotors de coupe et les matériaux se trouvent dans l'aide à la sélection. Des jeux d'outils de coupe sont également disponibles en d'autres matériaux.

JEUX D'OUTILS DE COUPE EN ACIER INOXYDABLE DIFFÉRANT ET CARBURE DE TUNGSTÈNE

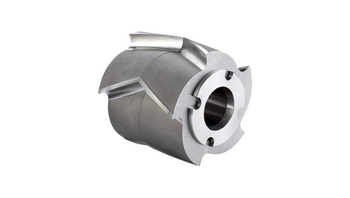

The standard rotor made of hardened stainless steel with V-cutting edges and fixed knives is suited primarily for comminution of tough-elastic materials and films due to its especially acute cutting angle and the high cutting action that results.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our cutting tool sets of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4112 |

| ISO/EN/DIN code | X90CrMoV18 / EN 10088 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 79 - 77 |

| Chromium – Cr | 17 - 19 |

| Silicon – Si | 1.0 |

| Manganese – Mn | 1.0 |

| Molybdenum – Mo | 0.9 - 1.3 |

| Carbon – C | 0.85 - 0.95 |

| Vanadium – V | 0.07 - 0.012 |

| Phosphorus – P | 0.04 |

| Sulphur – S | 0.015 |

| Physical and mechanical properties | |

| Density | 7.7 g/cm³ ; |

| Hardness | 56 - 58 HRC |

Explanations on hardness data

This rotor with V-cutting edges and fixed knives made of hardmetal tungsten carbide comminutes the grinding material through impact and cutting forces and is suitable for hard-tough materials.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our cutting tool sets of chromium-free tool steel.

| 1. Rotorknives | |

| General Specification | |

| Material | Hardmetal tungsten carbide – WC |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – WC | 88 |

| Cobalt – Co | 12 |

| Physical and mechanical properties | |

| Density | 12.4 g/cm³ |

| Hardness | 89.5 HRA |

| 2. Rotorbody | |

| General specifications | |

| Material | Stainless steel– 1.4404 |

| ISO/EN/DIN Code | X2CRNiMO17-12-2 /DIN SEW410 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 68.3 - 62.8 |

| Chromium – Cr | 16.5. - 18.5 |

| Nickel – Ni | 10.0 - 13.0 |

| Molybdenum – Mo | 2.0 - 2.5 |

| Manganese – Mn | 2.0 |

| Silicon – Si | 1.0 |

| Phosphorus – P | 0.045 |

| Carbon – C | 0.03 |

| Sulphur – S | 0.015 |

| Other – | 0.11 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 45 HB |

Explanations on hardness data

The rotor with notched edges and fixed knives made of hardened stainless steel is ideal for comminuting samples with residual moisture, such as food, feed or plants, and temperature-sensitive samples, such as plastics.

Due to its notched edges, the grinding chamber never closes completely, thus allowing optimum air flow. This significantly increases the throughput and makes the use of very fine sieves for larger quantities possible in the first place. The rotor knives have two notched cutting edges and can be easily turned after one side is used up.

Your advantage: twice the service life.

| General specifications | |

| Material | Stainless steel – 1.4112 |

| ISO/EN/DIN code | X90CrMoV18 / EN 10088 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 79 - 77 |

| Chromium – Cr | 17 - 19 |

| Silicon – Si | 1.0 |

| Manganese – Mn | 1.0 |

| Molybdenum – Mo | 0.9 - 1.3 |

| Carbon – C | 0.85 - 0.95 |

| Vanadium – V | 0.07 - 0.012 |

| Phosphorus – P | 0.04 |

| Sulphur – S | 0.015 |

| Physical and mechanical properties | |

| Density | 7.7 g/cm³ ; |

| Hardness | 56 - 58 HRC |

Explanations on hardness data

The rotor with notched edges and fixed knives made of stainless steel 316L is ideal for comminuting samples with residual moisture, such as food, feed or plants, and temperature-sensitive samples, such as plastics.

Due to the material used, the rotor is resistant to alkalis and acids and complies with the guidelines of the food and pharmaceutical industry – thus it’s perfect for the analytical sector and for sample preparation with special focus on increased resistance to corrosion.

Due to its notched edges, the grinding chamber never closes completely, thus allowing optimum air flow. This significantly increases the throughput and makes the use of very fine sieves for larger quantities possible in the first place. The rotor knives have two notched cutting edges and can be easily turned after one side is used up.

Your advantage: twice the service life.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The rotor made of tool steel with straight cutting edges which run parallel to the fixed knives is suitable for easily cut material, such as hay, straw, fibrous or biological materials. The rotor knives may be turned, since they have 2 cutting edges. Your advantage: doubling the life span of your rotor knives.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our cutting tool sets of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4112 |

| ISO/EN/DIN code | X90CrMoV18 / EN 10088 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 79 - 77 |

| Chromium – Cr | 17 - 19 |

| Silicon – Si | 1.0 |

| Manganese – Mn | 1.0 |

| Molybdenum – Mo | 0.9 - 1.3 |

| Carbon – C | 0.85 - 0.95 |

| Vanadium – V | 0.07 - 0.012 |

| Phosphorus – P | 0.04 |

| Sulphur – S | 0.015 |

| Physical and mechanical properties | |

| Density | 7.7 g/cm³ ; |

| Hardness | 56 - 58 HRC |

Explanations on hardness data

The rotor made of stainless steel 316L with straight cutting edges which run parallel to the fixed knives is suitable for easily cut material, such as hay, straw, fibrous or biological materials. Due to the material used, the rotor is resistant to alkalis and acids and complies with the guidelines of the food and pharmaceutical industry – thus it’s perfect for the analytical sector and for sample preparation with special focus on increased resistance to corrosion.

The rotor knives may be turned, since they have 2 cutting edges. Your advantage: doubling the life span of your rotor knives.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our cutting tool sets of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Disk milling cutter rotor: The especially robust disk milling cutter rotor with indexable inserts and fixed knives made of hardmetal tungsten carbide can even comminute circuit board scrap with glass fibre residue and copper cable.

Quadruple service life: With the disk milling cutter rotor, the cutting plates can be turned four times and replaced individually. Damage or wear are no longer a reason to buy a completely new rotor.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our cutting tool sets of chromium-free tool steel.

| 1. Rotorknives | |

| General Specification | |

| Material | Hardmetal tungsten carbide – WC |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – WC | 88 |

| Cobalt – Co | 12 |

| Physical and mechanical properties | |

| Density | 12.4 g/cm³ |

| Hardness | 89.5 HRA |

| 2. Rotorbody | |

| General specifications | |

| Material | Stainless steel– 1.4404 |

| ISO/EN/DIN Code | X2CRNiMO17-12-2 /DIN SEW410 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 68.3 - 62.8 |

| Chromium – Cr | 16.5. - 18.5 |

| Nickel – Ni | 10.0 - 13.0 |

| Molybdenum – Mo | 2.0 - 2.5 |

| Manganese – Mn | 2.0 |

| Silicon – Si | 1.0 |

| Phosphorus – P | 0.045 |

| Carbon – C | 0.03 |

| Sulphur – S | 0.015 |

| Other – | 0.11 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 45 HB |

Explanations on hardness data

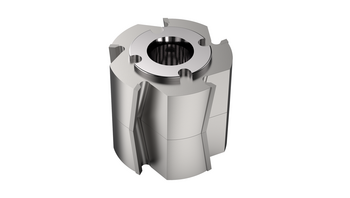

The disk milling cutter rotor with large chip chambers, indexable inserts and fixed knives made

of hardmetal tungsten carbide is suited for grinding large sample amounts.

The especially robust disk milling cutter rotor with large chip chambers, indexable inserts and fixed knives can even comminute circuit board scrap with glass fibre residue and copper cable.

Quadruple service life: With the disk milling cutter rotor, the cutting plates can be turned four times and replaced individually. Damage or wear are no longer a reason to buy a completely new rotor.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our cutting tool sets of chromium-free tool steel.

| 1. Rotorknives | |

| General Specification | |

| Material | Hardmetal tungsten carbide – WC |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – WC | 88 |

| Cobalt – Co | 12 |

| Physical and mechanical properties | |

| Density | 12.4 g/cm³ |

| Hardness | 89.5 HRA |

| 2. Rotorbody | |

| General specifications | |

| Material | Stainless steel– 1.4404 |

| ISO/EN/DIN Code | X2CRNiMO17-12-2 /DIN SEW410 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 68.3 - 62.8 |

| Chromium – Cr | 16.5. - 18.5 |

| Nickel – Ni | 10.0 - 13.0 |

| Molybdenum – Mo | 2.0 - 2.5 |

| Manganese – Mn | 2.0 |

| Silicon – Si | 1.0 |

| Phosphorus – P | 0.045 |

| Carbon – C | 0.03 |

| Sulphur – S | 0.015 |

| Other – | 0.11 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 45 HB |

Explanations on hardness data

Cassettes à tamis en acier inoxydable 316L

Les cassettes à tamis déterminent la granulométrie finale de l'échantillon. Elles assurent un écart constant entre le rotor et l'échantillon et donc le meilleur résultat possible. Des cassettes à tamis à perforation trapézoïdale et à perforation carrée sont disponibles. Les cassettes à tamis à perforation trapézoïdale provoquent une fragmentation supplémentaire résultant du cisaillement plus important. Les cassettes à tamis à perforation carrée sont recommandées pour fragmenter des matériaux cassants et des matériaux de finesse moyenne à plage granulométrique étroite. Les cassettes à tamis sont aussi disponibles avec d'autres perforations.

CASSETTES À TAMIS EN ACIER INOXYDABLE 316L

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band. They are laser-welded and offer significantly easier cleaning due to less dead spaces. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achiving medium fineness with a narrow grain band. They are laser-welded and offer significantly easier cleaning due to less dead spaces. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band. They are laser-welded and offer significantly easier cleaning due to less dead spaces. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band. They are laser-welded and offer significantly easier cleaning due to less dead spaces. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band. They are laser-welded and offer significantly easier cleaning due to less dead spaces. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band. They are laser-welded and offer significantly easier cleaning due to less dead spaces. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

ACCESSOIRES POUR BROYAGE SANS CHROME

-

Caractéristiques des jeux d'outils de coupe de broyage sans chrome et applications recommandées

Matériau et type de rotor Composant principal du matériau Résistance à l'abrasion Densité en g/cm³ Convient au broyage de acier à outil sans chrome Fe relativement bonne 7,8 Rotor avec lames en V et contre-couteaux

référence 45.5112.00

Rotor avec couteaux droits et contre-couteaux

référence 45.5012.00

Les deux rotors sont parfaitement adaptés à la préparation d'échantillons selon RoHS, par exemple pour prouver la présence de chrome hexavalent et pour l'analyse XRFéchantillons cassants, durs, matériaux et films viscoélastiques

échantillons cassants et durs et matériaux facilement sectionnables de type foin, paille, matériaux fibreux et biologiques

Lorsqu'une préparation d'échantillon conforme à RoHS (destinée par exemple à prouver la présence de chrome hexavalent) ou à des analyses XRF doit impérativement assurer une fragmentation garantie sans chrome, les jeux d'outils de coupe FRITSCH en acier à outil sans chrome et les cassettes à tamis en acier sans chrome DC01 vous donnent la sécurité nécessaire.

JEUX D'OUTILS DE COUPE EN ACIER À OUTIL SANS CHROME

The rotors made of chromium-free tool steel are especially recommended for the sample preparation according to RoHS and for the XRF-analysis. If a chromium-free size reduction is required for sample preparation according to RoHS – for example for verification of hexavalent chromium – or for XRF analysis, FRITSCH cutting tool sets of chromium-free tool steel offer this absolute assurance. Because for FRITSCH Cutting Mills, the fixed knives are always of the same material as the cutting edges of the rotor.

This rotor with V-cutting edges and fixed knives made of chromium-free tool steel is suited primarily for comminution of tough-elastic materials and films due to its especially acute cutting angle and the high cutting action that results.

For all other applications we recommend our cutting tool set made of tool steel and hardmetal tungsten carbide, since these are harder and therefore more resilient against abrasion.

| General specifications | |

| Material | Construction steel - 1.0330 - not rust-proof |

| ISO/EN/DIN code | DC01, EN 1013 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 99.19 |

| Carbon – C | 0.12 |

| Manganese – Mn | 0.6 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 86 HRA |

Explanations on hardness data

The rotors made of chromium-free tool steel are especially recommended for the sample preparation according to RoHS and for the XRF-analysis. If a chromium-free size reduction is required for sample preparation according to RoHS – for example for verification of hexavalent chromium – or for XRF analysis, FRITSCH cutting tool sets of chromium-free tool steel offer this absolute assurance. Because for FRITSCH Cutting Mills, the fixed knives are always of the same material as the cutting edges of the rotor.

The rotor made of chromium-free tool steel with straight cutting edges which run parallel to the fixed knives is suitable for easily cut material, such as hay, straw, fibrous or biological materials. The rotor knives may be turned, since they have 2 cutting edges. Your advantage: doubling the life span of your rotor knives.

For all other applications, we recommend our cutting tool set made of tool steel and hardmetal tungsten carbide, since these are harder and therefore more resilient against abrasion.

| General specifications | |

| Material | Construction steel - 1.0330 - not rust-proof |

| ISO/EN/DIN code | DC01, EN 1013 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 99.19 |

| Carbon – C | 0.12 |

| Manganese – Mn | 0.6 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 86 HRA |

Explanations on hardness data

CASSETTES À TAMIS EN ACIER SANS CHROME DC01

Sieve cassettes determine the final fineness of a sample. Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and materials of medium fineness with a narrow grain band.

Sieve cassettes made of chromium-free steel DC01 are especially recommended for the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF analysis. For all other applications sieve cassettes made stainless steel can be used since these are harder and therefore more resilient against abrasion.

| General specifications | |

| Material | Construction steel - 1.0330 - not rust-proof |

| ISO/EN/DIN code | DC01, EN 1013 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 99.19 |

| Carbon – C | 0.12 |

| Manganese – Mn | 0.6 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 86 HRA |

Explanations on hardness data

Sieve cassettes made of chromium-free steel DC01 are especially recommended for the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF analysis. For all other applications sieve cassettes made stainless steel can be used since these are harder and therefore more resilient against abrasion.

Sieve cassettes determine the final fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and materials of medium fineness with a narrow grain band.

| General specifications | |

| Material | Construction steel - 1.0330 - not rust-proof |

| ISO/EN/DIN code | DC01, EN 1013 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 99.19 |

| Carbon – C | 0.12 |

| Manganese – Mn | 0.6 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 86 HRA |

Explanations on hardness data

Sieve cassettes made of chromium-free steel DC01 are especially recommended for the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF analysis. For all other applications sieve cassettes made stainless steel can be used since these are harder and therefore more resilient against abrasion.

Sieve cassettes determine the final fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and materials of medium fineness with a narrow grain band.

| General specifications | |

| Material | Construction steel - 1.0330 - not rust-proof |

| ISO/EN/DIN code | DC01, EN 1013 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 99.19 |

| Carbon – C | 0.12 |

| Manganese – Mn | 0.6 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 86 HRA |

Explanations on hardness data

Sieve cassettes made of chromium-free steel DC01 are especially recommended for the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF analysis. For all other applications sieve cassettes made stainless steel can be used since these are harder and therefore more resilient against abrasion.

Sieve cassettes determine the final fineness of a sample.

Sieve inserts with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and materials of medium fineness with a narrow grain band.

| General specifications | |

| Material | Construction steel - 1.0330 - not rust-proof |

| ISO/EN/DIN code | DC01, EN 1013 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 99.19 |

| Carbon – C | 0.12 |

| Manganese – Mn | 0.6 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 86 HRA |

Explanations on hardness data

Sieve cassettes made of chromium-free steel DC01 are especially recommended for the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF analysis. For all other applications sieve cassettes made stainless steel can be used since these are harder and therefore more resilient against abrasion.

Sieve cassettes determine the final fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and materials of medium fineness with a narrow grain band.

| General specifications | |

| Material | Construction steel - 1.0330 - not rust-proof |

| ISO/EN/DIN code | DC01, EN 1013 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 99.19 |

| Carbon – C | 0.12 |

| Manganese – Mn | 0.6 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 86 HRA |

Explanations on hardness data

Sieve cassettes made of chromium-free steel DC01 are especially recommended for the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF analysis. For all other applications sieve cassettes made stainless steel can be used since these are harder and therefore more resilient against abrasion.

Sieve cassettes determine the final fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and materials of medium fineness with a narrow grain band.

| General specifications | |

| Material | Construction steel - 1.0330 - not rust-proof |

| ISO/EN/DIN code | DC01, EN 1013 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 99.19 |

| Carbon – C | 0.12 |

| Manganese – Mn | 0.6 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 86 HRA |

Explanations on hardness data

Sieve cassettes made of chromium-free steel DC01 are especially recommended for the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF analysis. For all other applications sieve cassettes made stainless steel can be used since these are harder and therefore more resilient against abrasion.

Sieve cassettes determine the final fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and materials of medium fineness with a narrow grain band.

| General specifications | |

| Material | Construction steel - 1.0330 - not rust-proof |

| ISO/EN/DIN code | DC01, EN 1013 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 99.19 |

| Carbon – C | 0.12 |

| Manganese – Mn | 0.6 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 86 HRA |

Explanations on hardness data

Dispositif d'aspiration d'échantillon avec cyclones

La combinaison brevetée du broyeur à couteaux universel et du cyclone haute performance le nettoyage et le remplissage, permet d'utiliser des cassettes à tamis plus fines pour obtenir des granulométries finales plus petites, accélère le débit, maintient la contrainte thermique des échantillons à un niveau réduit, même lorsque les échantillons sont difficiles à broyer.

Cyclone haute performance

The Fritsch high-performance Cyclone completely made of stainless steel 316L is particularly indispensable in the analytical sector and in the food and pharmaceutical industries, and for the processing of heterogeneous mixtures of material, e.g. in the cement industry.

Due to its high surface quality, it offers enhanced resistance to corrosive media such as alkalis and acids and is especially easy to clean with a wide range of possible cleaning agents, without leaving any residues. The comminuted sample is drawn into a screwed-on collecting vessel or in a smaller sample glass, in which it can also be transported and stored. In addition, it can be completely dismantled, fully emptied, flooded and sterilised, and thus offers reliable protection against cross-contamination.

The advantages of the high-performance Cyclone at a glance

- Faster throughput

- Improved discharge of material from the grinding chamber

- Additional strong cooling of the grinding material and grinding parts

- Efficient size reduction of temperature-sensitive samples, electrostatically-charged plastics or powder coatings

- Ideal for light materials, small sample quantities and finer sieve sizes

- Highly efficient continuous comminution of large quantities

| General specifications | |

| Material | Stainless steel – 1.4301 |

| ISO/EN/DIN code | X5CrNi1810 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 66.805 |

| Carbon – C | 0.070 |

| Silicon – Si | 1.000 |

| Manganese – Mn | 2.000 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.030 |

| Chromium – Cr | 19.5 |

| Nickel – Ni | 10.5 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 7.8 g/cm³ |

| Hardness | HRB 96 |

Explanations on hardness data

Inline sight glass 316L for visual inspection of sample exhaustion, possible applications:

• Cutting Mill P-19: between high-performance cyclone (19.1907.00) and collecting vessel 60 litres (45.8050.00)

• Cutting Mill P-19 large: between high-performance cyclone (19.4907.00) and collecting vessel 60 litres (45.8050.00)

• Rotor Mills P-14 and P-16: between the respective high-performance cyclone and collecting vessel 60 litres

• Disk Mill P-13 premium and P-13: between the respective high-performance cyclone and collecting vessel 60 litres

Ideal for observing the material flow during sample exhaustion.

The Fritsch high-performance cyclone completely made of stainless steel 316L is particularly indispensable in the analytical sector and in the food and pharmaceutical industries, and for the processing of hetero geneous mixtures of material, e.g. in the cement industry. Due to its high surface quality, it offers enhanced resistance to corrosive media such as alkalis and acids and is especially easy to clean with a wide range of possible cleaning agents, without leaving any residues. In addition, it can be completely dismantled, fully emptied, flooded and sterilised, and thus offers reliable protection against cross-contamination. The comminuted sample is drawn into a screwed-on collecting vessel or in a smaller sample glass, in which it can also be transported and stored.

The high-performance cyclone with solid piping should be used in combination with the stand with wheels (order no. 45.5800.00).

The advantages of the high-performance cyclone at a glance

- Faster throughput

- Improved discharge of material from the grinding chamber

- Additional strong cooling of the grinding material and grinding parts

- Efficient size reduction of temperature-sensitive samples, electrostatically-charged plastics or powder coatings

- Ideal for light materials, small sample quantities and finer sieve sizes

- Highly efficient continuous comminution of large quantities

| General specifications | |

| Material | Stainless steel – 1.4301 |

| ISO/EN/DIN code | X5CrNi1810 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 66.805 |

| Carbon – C | 0.070 |

| Silicon – Si | 1.000 |

| Manganese – Mn | 2.000 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.030 |

| Chromium – Cr | 19.5 |

| Nickel – Ni | 10.5 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 7.8 g/cm³ |

| Hardness | HRB 96 |

Explanations on hardness data

Récipients collecteur pour cyclones haute performance

Sample glass 1 litre for sample exhaustion with the high-performance Cyclone separator.

The sample glass with 2 litres volume is recommended for sample exhaustion with the high-performance Cyclone separator for sample discharges larger than 1000 ml, since only a 1 litre sample glass is included in the delivery of the high-performance Cyclone separator.

The sample glass with 5 litres volume is recommended for sample exhaustion with the high-performance Cyclone separator for sample discharges larger than 1000 ml, since only a 1 litre sample glass is included in the delivery of the high-performance Cyclone separator.

The collecting vessel 20 litres is recommended for sample exhaustion with the high-performance Cyclone separator for sample discharges larger than 1000 ml, since only a 1 litre sample glass is included in the delivery of the high-performance Cyclone separator.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The collecting vessel 60 litres is recommended for sample exhaustion with the high-performance Cyclone separator for sample discharges larger than 1000 ml, since only a 1 litre sample glass is included in the delivery of the high-performance Cyclone separator.

The collecting vessel 60 litres can not be used due to its size in combination with the high-performance cyclone separator with solid piping, order no. 19.1940.00 (P-19) or order no. 19.1947.00 (P-19 large).

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Cyclone pour petites quantités

Small volume Cyclone separator made of plastic, food-grade, for sample exhaustion of small sample quantities, incl. 500 ml sample glass.

Especially for exhaustion of small sample quantities, we designed the compact FRITSCH small volume Cyclone separator. It is made of plastic, can be dismantled completely and cleaned in a dishwasher for reliably preventing contaminations. The FRITSCH small volume Cyclone separator must be connected to an exhaust system: order no. 43.9070.00.

Especially convenient: The comminuted sample is drawn directly into the screwed-on 500 ml sample glass, in which it can also be transported and stored. Alternatively a sample glass 250 ml can also be screwed-on and ordered: order no. 27.1450.00.

Récipients collecteurs pour cyclone pour petites quantités

Sample bottle with screw lid, thread of sample bottle GL55, sample bottle can be used with dividing heads, division ratio 1:8 and 1:10.

Furthermore a sample vessel 32 ml with lid, article-number 83.3190.16, is available, which can be inserted in the sample bottles 250 ml and 500 ml for dividing smallest sample quantities.

The sample glass is recommended for sample exhaustion with the small volume Cyclone separator for sample discharges smaller than 500 ml, since only a 500 ml sample glass is included in the delivery of the small volume performance Cyclone separator.

Sample bottle with screw lid, thread of sample bottle GL55.

Sample bottle can be used with dividing heads, division ratio 1:8.

Furthermore a sample vessel 32 ml with lid, article-number 83.3190.16, is available, which can be inserted in the sample bottles 250 ml and 500 ml for dividing smallest sample quantities.

Sample glass can also be used for sample exhaustion with the small volume Cyclone separator.

Système d'aspiration et accessoires pour cyclone haute performanc et cyclone pour petites quantités

With the switch box, you control the exhaust system directly via the Cutting Mills P-19 | P-19 large. Due to the switch box, applicable for 100-240 V/1~, 50-60 Hz, up to 3600 Watt, the sample exhaustion with cyclones and exhaust system becomes even easier and more comfortable.

The exhaust system, dust category "M" according to DIN EN 60335-2-69 for 230 V/1~, 50/60 Hz, 1600 Watt is versatile:

For combination with the high performance and small volume cyclones.

To operate the FRITSCH Cyclones you need an exhaust system. The strong airflow ensures simple feeding, increases throughput, and reduces the thermal load of the samples. The high performance and small volume Cyclone separator can be combined with Universal Cutting Mills PULVERISETTE 19, the Rotor Mill P-14 and the Variable Speed Rotor Mill PULVERISETTE 14 classic line. The small volume cyclone can also be combined with the Rotor Mill P-14 premium line and Variable Speed Rotor Mill PULVERISETTE 14 classic line even for passive utilisation – without sample exhaust.

The high-performance cyclone is ideal for combination with the Universal Cutting Mills PULVERISETTE 19 large, the Cross Beater Mill PULVERISETTE 16 and the Disk Mill PULVERISETTE 13 premium line for optimal sample extraction and for comminution of larger quantities.

For cooling of the Rotor Mill P-14

By connecting the exhaust system with the connecting piece order no. 14.8128.00, the cooling of the mill can easily be enhanced.

For connecting to Disk Mill PULVERISETTE 13 premium line

The exhaust is simply connected to the PULVERISETTE 13 premium line and operated via a start and stop button on the instrument – for dust free comminution.

For connecting to the Jaw Crusher PULVERISETTE 1, Modell I + II classic line

Simply connect the exhaust system to the integrated connection of the PULVERISETTE 1. Fine dust arising during comminution is automatically removed. The exhaust system is also very useful when cleaning the grinding parts.

For connecting to the Disk Mill PULVERISETTE 13 classic line

The exhaust system can be easily connected to the PULVERISETTE 13 classic line. Fine dust arising during comminution is automatically removed. The exhaust system is also very useful when cleaning the grinding parts.

For exhaustion of the sample during dry measurement with the Laser Particle Sizers ANALYSETTE 22 NeXT

An exhaust system is necessary to ensure automatic sample exhaustion during dry measurement. When the measurement is completed it can also be easily used to manually clean the feeder.

Please note that the exhaust system article no. 43.9070.00, is not equipped with a fine filter and therefore dust may escape. Please consider the valid occupational health and safety regulations. This exhaust system is mostly recommended for dust-free grinding and the vacuuming of during the process developing fine dust in the upper part of the grinding chamber and for the cleaning of the grinding parts.

For vacuuming of the sample during dry measurement with the Laser Particle Sizers ANALYSETTE 22 NeXT, we recommended we recommend the exhaust system article no. 43.9060.00, which is equipped with a hose and an ultra-fine filter of dust class "H" according to DIN EN 60335-2-69, so that the escape of fine dust is reduced.

1 pack = 5 pieces

One pack is included in the scope of delivery of the exhaust system (article No. 43.9070.00).

These fleece filter bags should be used for the vacuuming off of fine, dry materials.

For the vacuuming off of coarse, wet materials are plastic bags available (article no. 43.9052.00).

1 pack = 5 pieces

One pack is included in the order of the exhaust system (article No. 43.9070.00).

These plastic bags should be used for the vacuuming off of coarse, wet materials.

For the vacuuming off of fine, dry materials are paper filter bags available (article no. 43.9055.00).

1 set = 2 pieces

One filter set is included in the order of the exhaust system (article No. 43.9070.00).

Supports

Un support universel, un support en acier inoxydable 316L, un support à roulettes ou un support des table sont disponibles. Ils représente une base très stable, peu encombrante et à géométrie variable pour le broyeur.

SUPPORTS

Stand for free installation of the following devices:

Universal Cutting Mill PULVERISETTE 19 variable speed 300-3000 rpm

Universal Cutting Mill PULVERISETTE 19 variable speed 50-700 rpm

Universal Cutting Mill PULVERISETTE 19 variable speed 50-700 rpm large

Universal Cutting Mill PULVERISETTE 19 variable speed 300-3000 rpm Large

Cross Beater Mill PULVERISETTE 16 with grinding insert made of cast iron

Cross Beater Mill PULVERISETTE 16 with grinding insert made of stainless steel

The PULVERISETTE 19 is shown as an example in the photo.

Stand cpl. welded, electrochemically polished made of stainless steel 316L.

This stand is also recommended and used for the free installation the following models of the Universal-Cutting Mills PULVERISETTE 19 300-3000 rpm and 50-700 rpm in the corrosion resistant stainless steel version 316 L, as well as for the PULVERISETTE 19 large 300-3000 rpm and PULVERISETTE 19 large 50-700 rpm.

The stand with wheels offers the Universal Cutting Mills PULVERISETTE 19 a space-saving and spatially variable basis.

A table-top stand with a height of approx. 330 mm is offered for the Universal Cutting Mills, Both, the PULVERISETTE 19 and PULVERISETTE 19 large can simply be screwed onto the stand.

Accessoires

Pour nos broyeurs, nous proposons des poussoirs d'échantillons pratiques.

poussoir

Sample pusher spiral-shaped made of POM plastic for stable feeding without rebound.

Ideal for feeding bulk solids such as for example grain, feed pellets or maize. The material flows directly into the cutting mill via the spiral-shaped sample pusher.

| General specifications | |

| Material | POM Polyoxymethylene |

| ISO/EN/DIN Code | DIN 7728 C9021 |

| Chemical composition | |

| Element | Formula |

| Polyoxmethylenecopolymer (Polyacetale) | CxH2xOx |

| Melting point | 165° C |

| max. Application temp. constant | 90° |

| max. Application temp. briefly | 140° |

| Chemical Resistance | |

| Aliphatical hydrocarbon | |

| Aromatical hydrocarbon | |

| Halogenised hydrocarbon | |

| weak acid | |

| strong alkaline solution | |

| Physical and mechanical properties | |

| Density | 141,g /cm³ |

| Hardness | extremely hard |

CERTIFICATION

Documentation IQ/OQ (formulaire - à remplir soi-même) aidant à la qualification du matériel dans le service de gestion de qualité, pour le broyeur universel à couteaux PULVERISETTE 19.

CERTIFICATION

IQ/OQ documentation (questionnaire format - implementation by customer) for the independent utilization for the support of instrument qualification in the quality management system for the Universal Cutting Mills PULVERISETTE 19.